LAKRIL: Turning Corn Into Tomorrow’s Green Chemicals

A conversation with new CEO Justin Brown

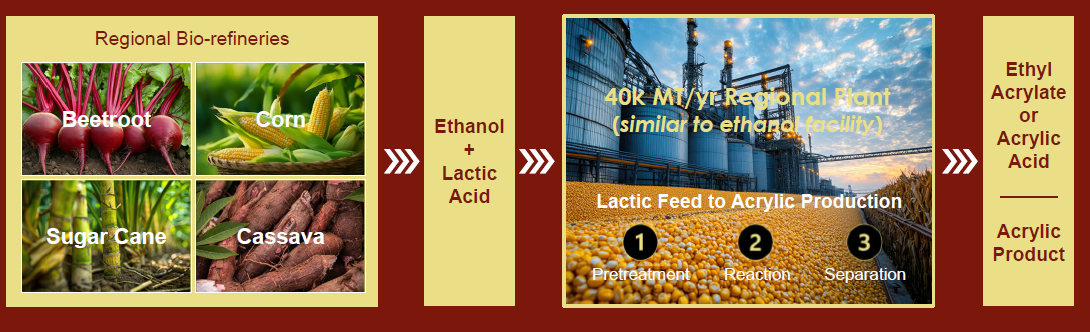

When you ask new Lakril CEO Justin Brown what the company does, he keeps it simple: “We take bio-based sugars (like those from corn) and turn them into green chemicals used around the world,” he says. “If you’ve used diapers, medical bandages, adhesives, or paint, you’ve used the products we feed into.”

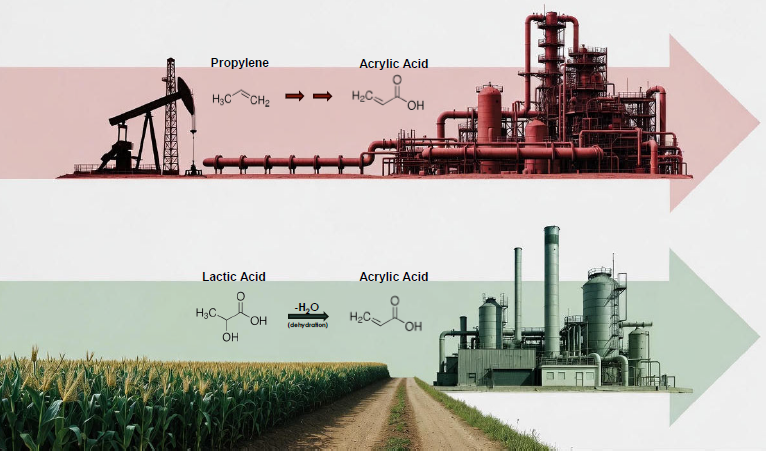

That “green chemical” is acrylic acid and its derivatives—part of a $12 billion+ global market. Today, all acrylic acid is made from petroleum. Lakril’s breakthrough technology changes that, using corn-based sugars instead of fossil fuels while still delivering the exact same molecule manufacturers expect.

And here’s the key: Lakril can do it at cost parity. No premium for going green. No subsidy required. No regulatory risk. Just a drop-in replacement that performs and costs exactly the same - only with up to an 80% reduction in greenhouse gases.

For Illinois farmers, the math is simple:

More demand. More stability. More opportunities for value-added corn markets.

Why Illinois? The Answer Is Corn and Serendipity

Lakril didn’t choose Illinois by accident.

Brown and Christopher Nicholas (co-founder of Lakril) originally met while working at Honeywell UOP in Chicago, one of the world’s most respected refining petrochemical, and gas process licensors. Their network of collaborators, venture capital partners, and nonprofit supporters are also here.

But above all:

Chicago sits on the edge of the Corn Belt.

And the Corn Belt is key.

“Corn gives us a regional, reliable feedstock,” Brown says. “Being close to the farmers who grow it strengthens the entire supply chain. The Midwest is simply the right place for this technology.”

What It Means for Illinois Farmers

If you boil Lakril’s vision down to a single sentence, Brown says it plainly:

“We’re taking corn and turning it into products used in a $12-billion+ global market.”

And because the demand for acrylic acid grows 3%+ every year (and corn production grows with it) farmers benefit from a new, stable demand source that doesn’t rely on subsidies or policy shifts.

And the applications are everywhere:

- Interior and exterior paints

- Medical bandages

- Diapers and adult incontinence products

- Potting-soil water-retention beads

- Industrial adhesives

If it absorbs water or sticks to something, corn may soon be behind it.

From Lab Powder to Pilot Plant

Lakril started with a high-yield catalyst discovered at the University of Minnesota. Over the last three years, the team has run 800–900 iterations of the process in Illinois labs. Later this month, Lakril will start up its first fully continuous pilot plant in Chicago, their fourth plant on the path to commercialization.

Beginning in Q1 2026, companies in paints, adhesives, and super-absorbent polymers will test Lakril’s bio-based acrylic acid in their products.

Because the chemical is a perfect molecule-for-molecule match, customers can drop it directly into existing processes.

Meet the CEO

Brown joined Lakril less than two months ago, but his path to bio-based chemistry spans continents.

A third-generation engineer from Canada, Brown began his career working on a produce farm—picking pumpkins, apples, peas, squash, and strawberries. After earning a degree in materials engineering and an MBA, he spent years in Indonesia, Singapore, Houston, and the North Sea, working across energy, LNG, petrochemicals, and advanced materials.

He eventually landed in Chicago at Honeywell UOP, where he met Dr. Nicholas. The two now work in a “two-in-the-box” model—pairing a business leader with a science leader.

“When people hear ‘startup,’ they think risky,” Brown says. “But Chris is the smartest person I’ve ever met. He holds more than 120 patents. When he said this technology was real, I believed him. That’s why I joined.”

Brown’s passion is scaling innovative technologies from concept to global commercialization—a perfect match for where Lakril stands today.

What’s Ahead

- Late December: Pilot plant startup

- Q1 2026: Begin shipping samples

- 2026: Series A fundraising and growth planning

And when he thinks about corn’s role in the next decade, he’s clear:

“The future belongs to sustainable technologies that compete on price. Corn can absolutely be a major feedstock in that space — and now, it finally pencils out.”